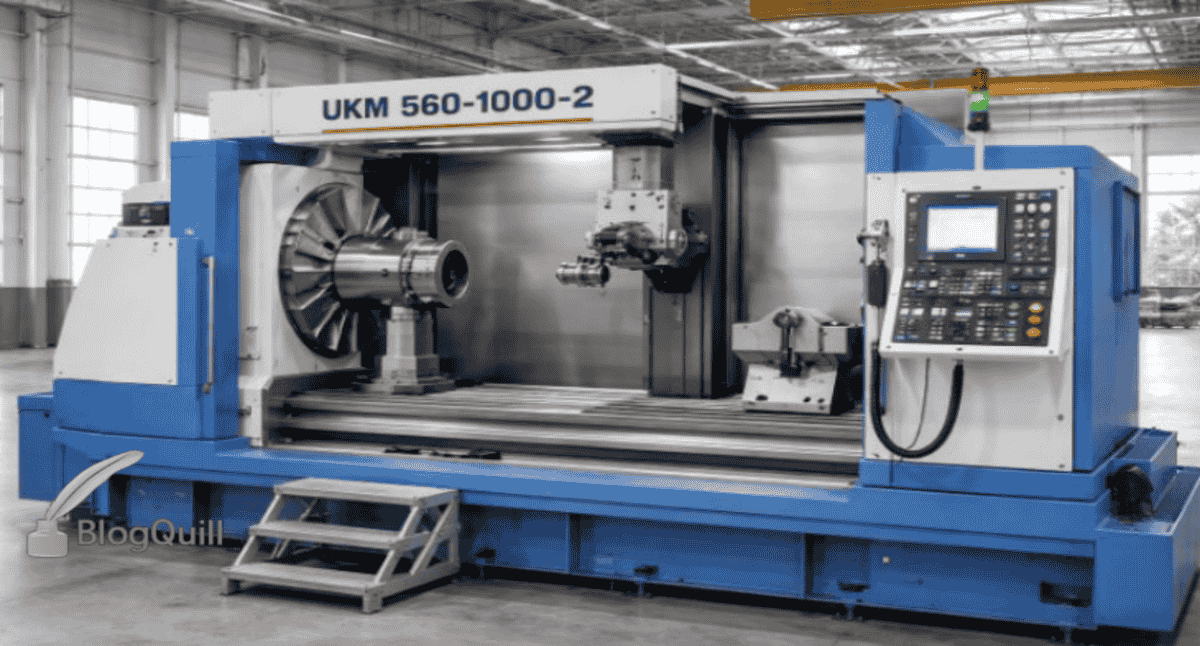

What Is UKM 560-1000-2? Meaning, Use, and Benefits

The UKM 560-1000-2 is a high precision industrial torque device. It is widely recognised in modern manufacturing for its reliability and performance. Engineered for professionals needing accurate measurements and consistent mechanical output, this model offers robust support. It is ideal for sectors where precision and efficiency are critical.

In simple terms, the UKM 560-1000-2 combines advanced engineering with durable construction. It is suitable for heavy-duty machinery and automated systems.

Its design ensures accurate readings and minimal downtime. Both are essential for maintaining production quality.

Where It’s Widely Used?

This is a tool that many different kinds of workers use in many places:

- Automotive Manufacturing:

It supports precise assembly, part fabrication, and engine component checks, improving overall production quality. - Aerospace and Defense:

This model ensures accurate alignment and testing of critical components, helping maintain stringent safety and regulatory standards. - Industrial Machinery:

By measuring and controlling mechanical motion, It helps stop mistakes and helps machines lifespan. - Medical Equipment Production:

High accuracy readings are crucial when fabricating surgical instruments and micro components. - Construction and Engineering:

Structural measurements and alignment of components benefit from its reliable performance.

Key Benefits

Investing in the UKM 560-1000-2 delivers several advantages:

- Enhanced Efficiency:

Fast and careful measuring helps work go smoothly without fixing mistakes again. - Cost Savings:

Long-lasting materials and reduced errors lower operational expenses. - Regulatory Compliance:

Adherence to industry standards ensures certification and quality benchmarks are maintained. - Safety and Reliability:

Accurate readings in critical uses mitigate risks and enhance confidence in system performance.

It is a helpful tool that many factory workers trust because it makes work easy, improve accuracy, efficiency, and long-term reliability.

How and where o Purchase the UKM 560-1000-2

If you want to get a UKM 560-1000-2, you should buy it from sellers who are certified or official distributors. This ensures the tool is genuine and not fake. Buying from the right places also provides a warranty, a promise that the company will help if something goes wrong. You will also get the right and proper instructions, technical support, and certificates that show the tool meets important safety and industry rules.

Before finalizing a transaction, it is recommended to review the manual PDF, request a datasheet download, and confirm warranty information. These steps protect against counterfeit units and ensure compatibility with your existing machinery systems.

Whether buying a new or used UKM 560-1000-2, choosing authorized vendors ensures long term reliability. It also provides access to spare parts and the support needed for safe industrial operation.

How to Keep It Running Smoothly

1- To make sure the tool works really well, it needs regular maintenance and careful handling.

2- Checking it often and taking care of it helps it stay accurate and reliable, and stops expensive problems from happening.

3- Start by looking at the important parts to see if anything is worn out or out of place.

4- Use the right lubricants and follow the tool’s instructions to make sure it measures correctly and works safely.

5- Keeping the tool clean and free of dust or dirt also helps it work well and last a long time.

6- It’s a good idea to have certified technicians service the tool regularly. They can check how it handles vibrations, recalibrate the sensors, and make sure it’s performing like it should. Writing down what they do during each maintenance visit helps track Damaged parts and can warn you about problems before they cause trouble.

7- For factories that use machines that work automatically, the UKM 560-1000-2 needs to be connected properly to these systems. This means making sure the parts line up correctly and the software is updated. Keeping everything aligned and checking the system’s feedback helps the machines run smoothly and stops unexpected problems.

By following these maintenance steps, manufacturers can get the most value from the UKM 560-1000-2, keep it working accurately, and make the machines last longer.

FAQs

This model transmits torque between shafts while maintaining alignment, reducing vibration, and providing precision measurement feedback for monitoring performance.

Key specifications include torque capacity, misalignment tolerance, vibration resistance, and calibration standards.

The device combines industrial engineering guide insights, robust construction, and advanced calibration standards, providing durability and minimal maintenance compared to other torque couplings.

It is widely used in automotive assembly, aerospace, heavy machinery, medical device production, and construction, supporting precise motion and measurement control.

Its high measurement accuracy and low vibration output ensure that machinery maintains quality standards, reduces rework, and improves operational efficiency.

Industries such as automotive, aerospace, industrial manufacturing, and medical equipment production benefit due to the device’s reliability, durability, and precision.

With proper care and periodic servicing, this heavy-duty machinery component UKM can operate effectively for several years.

Ensure correct installation, follow torque guidelines, inspect components regularly, and use approved lubricants to reduce mechanical risks.

Its precision measurement tool UKM 560‑1000‑2 capabilities provide highly reliable torque readings suitable for critical manufacturing and assembly processes.

Technical & Performance Questions

What are the technical specifications and data for UKM 560‑1000‑2?

Specifications include torque range, misalignment tolerance, vibration resistance, operational temperature limits, and calibration standards.

What is the measurement accuracy benchmark of UKM 560‑1000‑2?

Its performance aligns with UKM 560‑1000‑2 performance benchmarks vs industry standards, ensuring it meets strict industrial requirements.

Can UKM 560‑1000‑2 handle extreme torque loads?

Yes, the robust design supports heavy-duty torque applications while maintaining precise alignment.

What maintenance does UKM 560‑1000‑2 require?

Routine inspection, lubrication, and alignment checks are essential for maintain UKM 560‑1000‑2 calibration and standards.

How often should UKM 560‑1000‑2 be calibrated?

Calibration is recommended based on usage intensity and industrial regulations, typically every 3–6 months for high demand operations.

What are common issues when integrating UKM 560‑1000‑2 with automation systems?

Potential challenges include software compatibility, sensor misalignment, or mechanical wear, which can be minimized using the UKM 560‑1000‑2 integration with automation systems guide.

What environmental conditions can UKM 560‑1000‑2 withstand?

It is robust against dust, vibration, and temperature fluctuations in industrial environments.

Does UKM 560‑1000‑2 require special lubrication?

Yes, using manufacturer-recommended lubricants ensures smooth motion and maintains measurement accuracy.

Purchase & Support Questions

Where can I buy a UKM 560‑1000‑2?

Purchase from certified UKM 560‑1000‑2 sellers or authorized distributors to guarantee authenticity.

How much does UKM 560‑1000‑2 cost?

Pricing depends on specifications, vendor, and order size. Request an OEM dealer quote for accurate pricing.

Are there discount offers for bulk orders of UKM 560‑1000‑2?

Yes, verified distributors often provide UKM 560‑1000‑2 industrial equipment marketplace bulk pricing.

Can I buy a used UKM 560‑1000‑2 machine?

Yes, but only from certified sellers to ensure safety and authenticity.

Who are the authorized UKM 560‑1000‑2 distributors?

Check the official product page for a list of authorized vendors.

How do I find UKM 560‑1000‑2 OEM parts?

Use the UKM 560‑1000‑2 OEM parts lookup portal or authorized service centers.

Where can I download the UKM 560‑1000‑2 datasheet?

The datasheet download is available from official manufacturer websites.

Is there an official UKM 560‑1000‑2 manual PDF available?

Yes, the user guide online provides installation, calibration, and maintenance instructions.

How do I contact UKM 560‑1000‑2 technical support?

Reach out via UKM 560‑1000‑2 technical support resources for assistance..

Comparison & Evaluation Questions

How does UKM 560‑1000‑2 compare with UKM 560‑1500 models?

The 560‑1000‑2 focuses on precision and vibration control, whereas 560‑1500 may offer higher torque.

What are the pros and cons of UKM 560‑1000‑2?

Pros: high durability, precise measurement, easy integration.

Cons: higher initial cost, requires periodic calibration.

What are expert reviews of UKM 560‑1000‑2 performance?

Experts highlight reliable torque transmission, minimal maintenance, and superior industrial performance comparison with similar models.

What do customers say about UKM 560‑1000‑2 in testimonials?

Users report improved workflow, reduced errors, and high precision measurement feedback in operations.

Advanced / Niche Questions

Can UKM 560‑1000‑2 be integrated with modern smart factory systems?

Yes, it supports automated monitoring and real-time data collection in Industry 4.0 setups.

What’s the recommended install procedure for UKM 560‑1000‑2?

Follow the UKM 560‑1000‑2 industrial engineering guide: inspect shafts, align precisely, lubricate, and conduct a test run.

Is UKM 560‑1000‑2 compatible with variable speed drives?

Yes, proper alignment and calibration allow seamless operation with variable speed machinery.

How do I troubleshoot misalignment issues with UKM 560‑1000‑2?

Use alignment tools and follow UKM 560‑1000‑2 precision tool features instructions to adjust and correct deviations.

What are the best practices for extending the lifespan of UKM 560‑1000‑2?

Adhere to maintenance requirements, including regular inspection, lubrication, and periodic calibration.